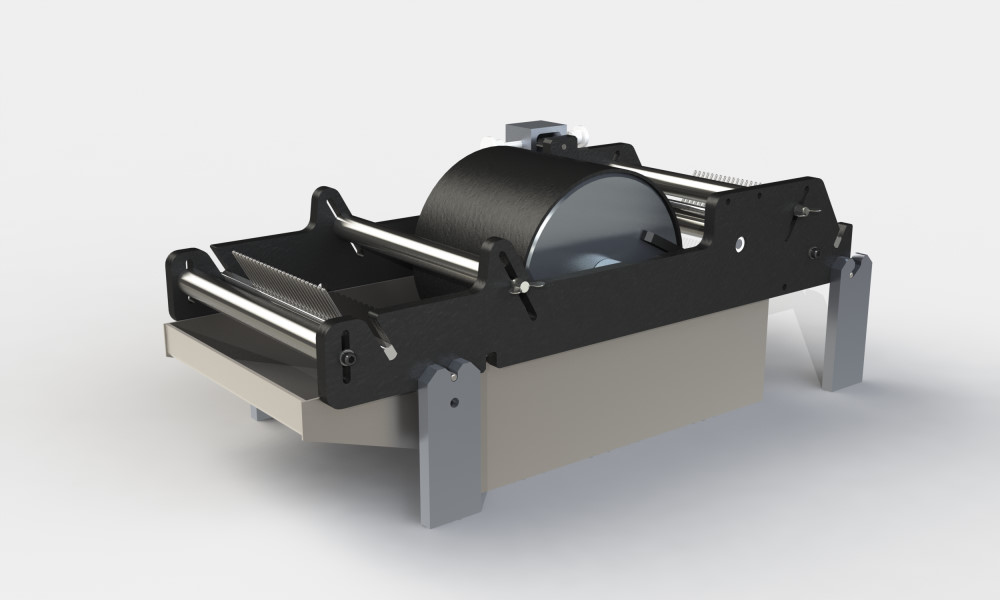

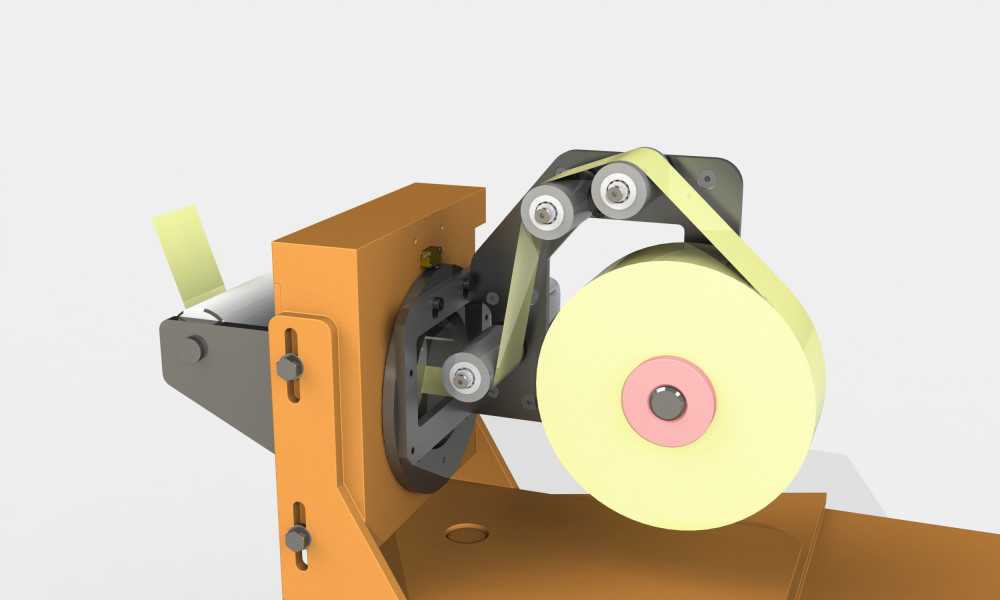

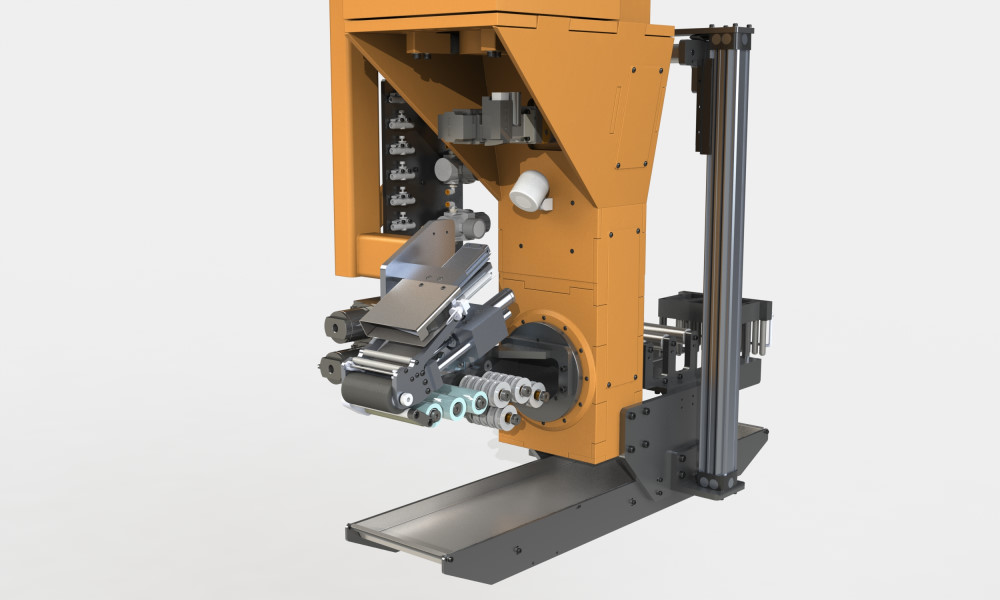

A 6.5″ wide drum can handle up to 20 tows and a 1.5-liter resin pan for production work. A heating option to warm up the resin is available.

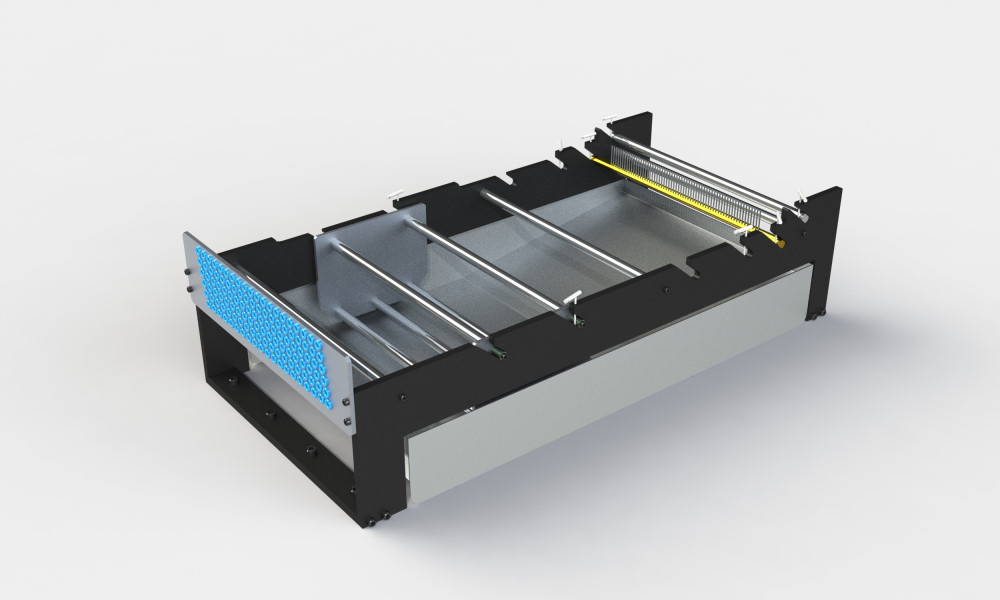

Supports resin impregnation for up to 60 tows. Adjustable drag bars and squeegees provide reliable resin content control. Ideal for applications requiring wide fiber bands or operations that use center-pull spools.

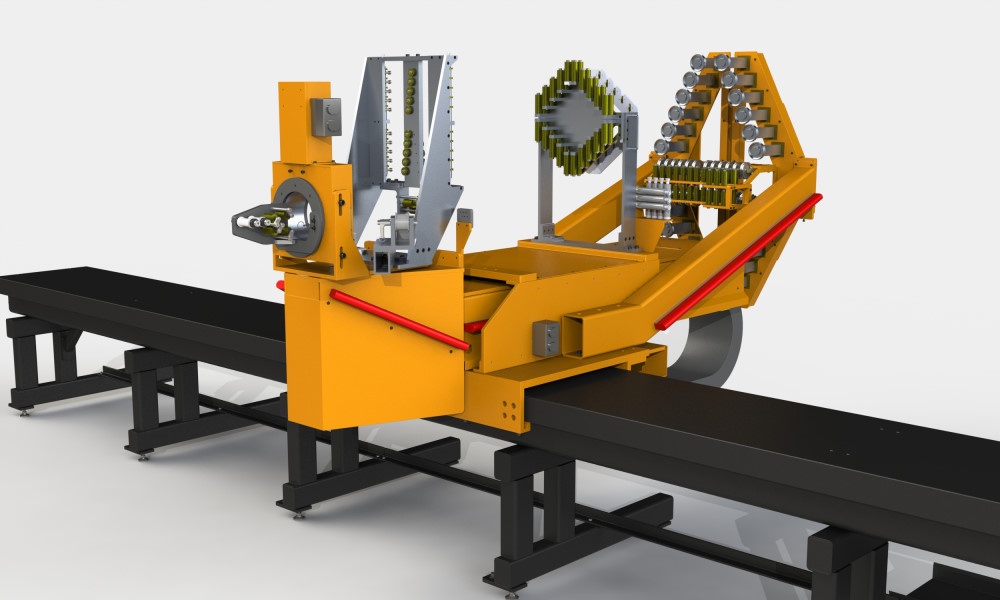

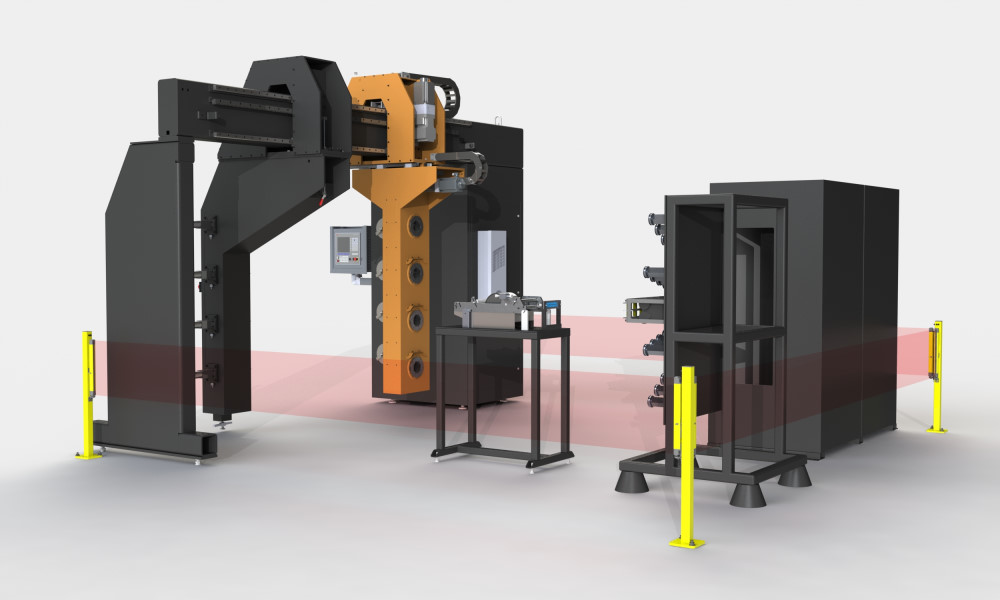

Delivers fiber from the tensioner to the delivery head, minimizing contact points and maximizing control. Each delivery system is customized for facility layout, fiber type, and number of tows.

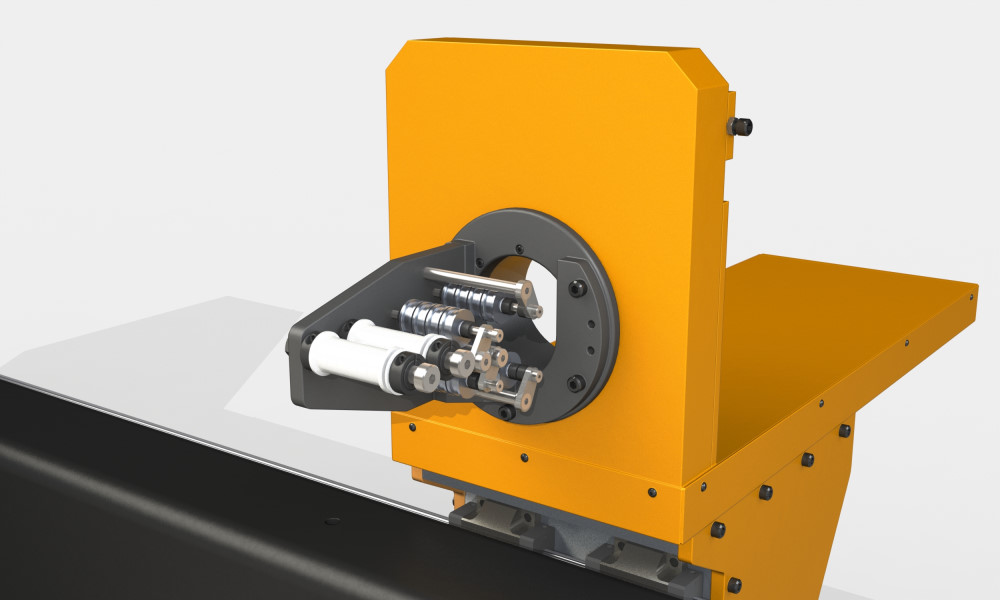

This delivery system provides the same level of control as the wet winding head but with all rolling contacts to work with today’s advanced towpreg fiber systems. Each head is configured for a specific tow width and number of tows.

The standard configuration provides flat bars, a comb, and a D-ring to adjust the fiber bandwidth and thickness. Custom D-ring radii, pin count, pin spacing, and additional fiber band adjusting options are available.

Shrink tapes, veils, and other spooled materials up to 3″ wide can be tensioned (up to 20 lbs) and placed onto mandrels with the same accuracy as fiber.

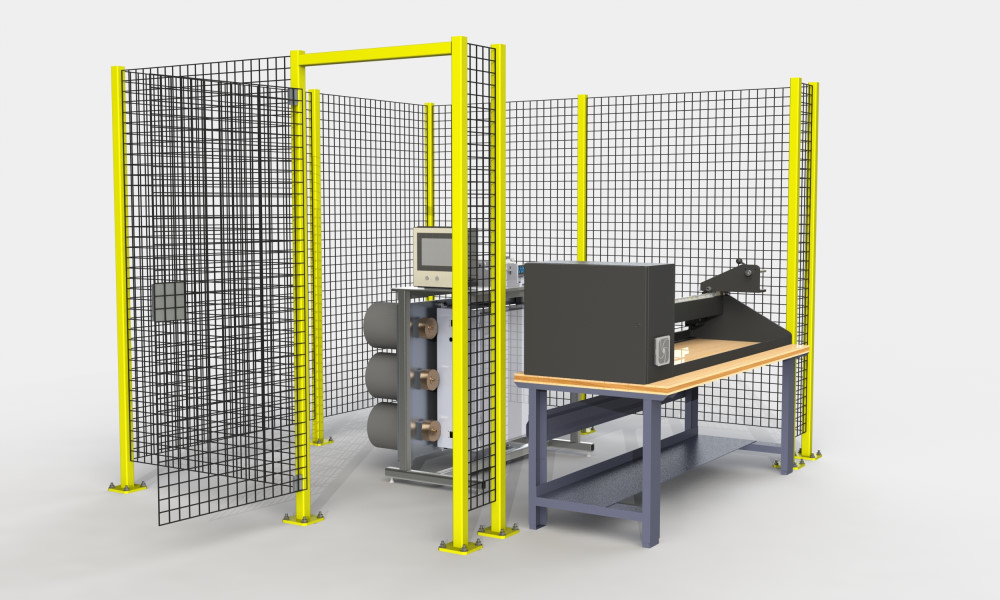

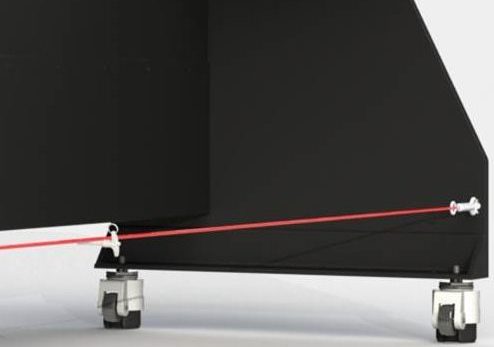

Provides a physical barrier around a workcell to keep operators safe from moving machinery. Safety fences can include interlocked doors for workcell access and be combined with Light Curtains and Foot Controls for customized safety needs.

Light curtains provide additional operator safety to protect hands, limbs, or bodies from touching moving components inside the work cell. The machinery will stop immediately when a beam is broken, ensuring a safe work environment.

Allow operators to maintain hand contact with the mandrels for tie-on/cut-off system or placing local reinforcement while still being able to rotate the mandrel (forward and reverse) or stop it immediately as needed with foot operation.

Process automation of fiber tensioning, tie-on, and cut-off operations before and after winding. Significantly reduces process time and manual operations while increasing quality and throughput. Available for wet winding and towpreg systems.

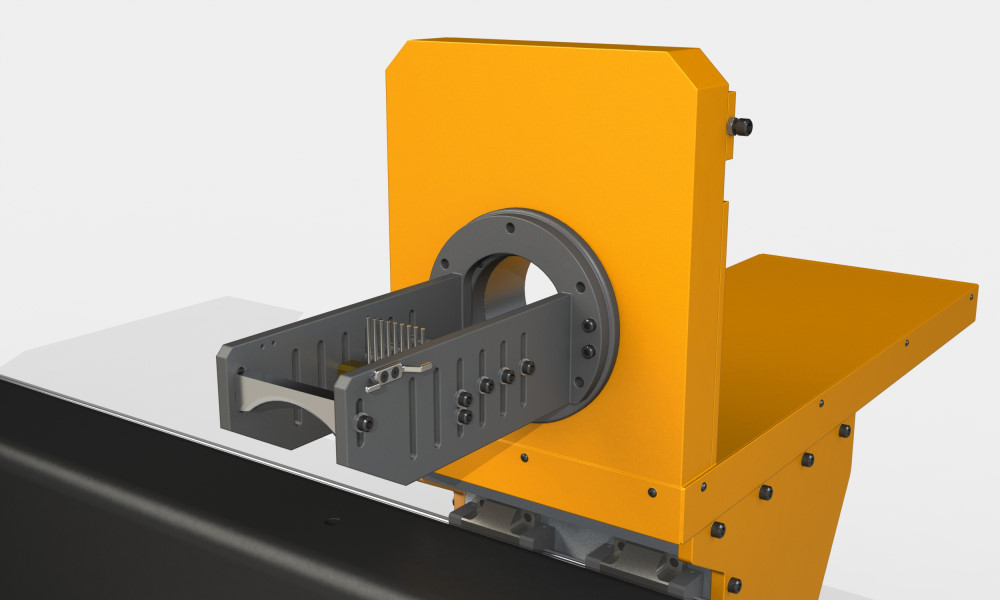

Solidly support mandrels with the addition of a tailstock chuck. Ideal for unbalanced mandrels or delicate mandrels that may not withstand the axial force of a live center. The mounted chuck can be easily swapped with a tailstock live center for mandrel supporting flexibility.

Allows to easily turn and move a machine in restricted spaces. Enable the technicians to move as well as lock work stands with minimal effort.