An innovative and compact tensioning creel was developed for high speed and accuracy. The configuration of the guide rollers reduces stringer wrap-ups and fuzz. The standard ST2 can hold up to sixteen 9-inch diameter bobbins in an 82”x72”x40” footprint. The system can be customized and is compatible with towpreg and wet winding systems. Learn more

The CAT tensioner creel uses sophisticated computer logic to accurately control fiber tension during winding. Each creel plugs directly into the filament winder control to adjust the tension on the fly if needed. The CAT creel accepts standard 9” diameter X 11” spools and is available with rewind for complex parts.

The bookshelf creel is a simple creel and matches with any center-pull fiber spool for easy setup and reliable winding. Adjustable S-wrap tension bars provide a quick means of tension control. Each creel can accommodate 15 spools of fiber and payoff from the front or side of the shelf. Shelves can also be positioned to allow 30 tows to exit from a single exit eyelet plate.

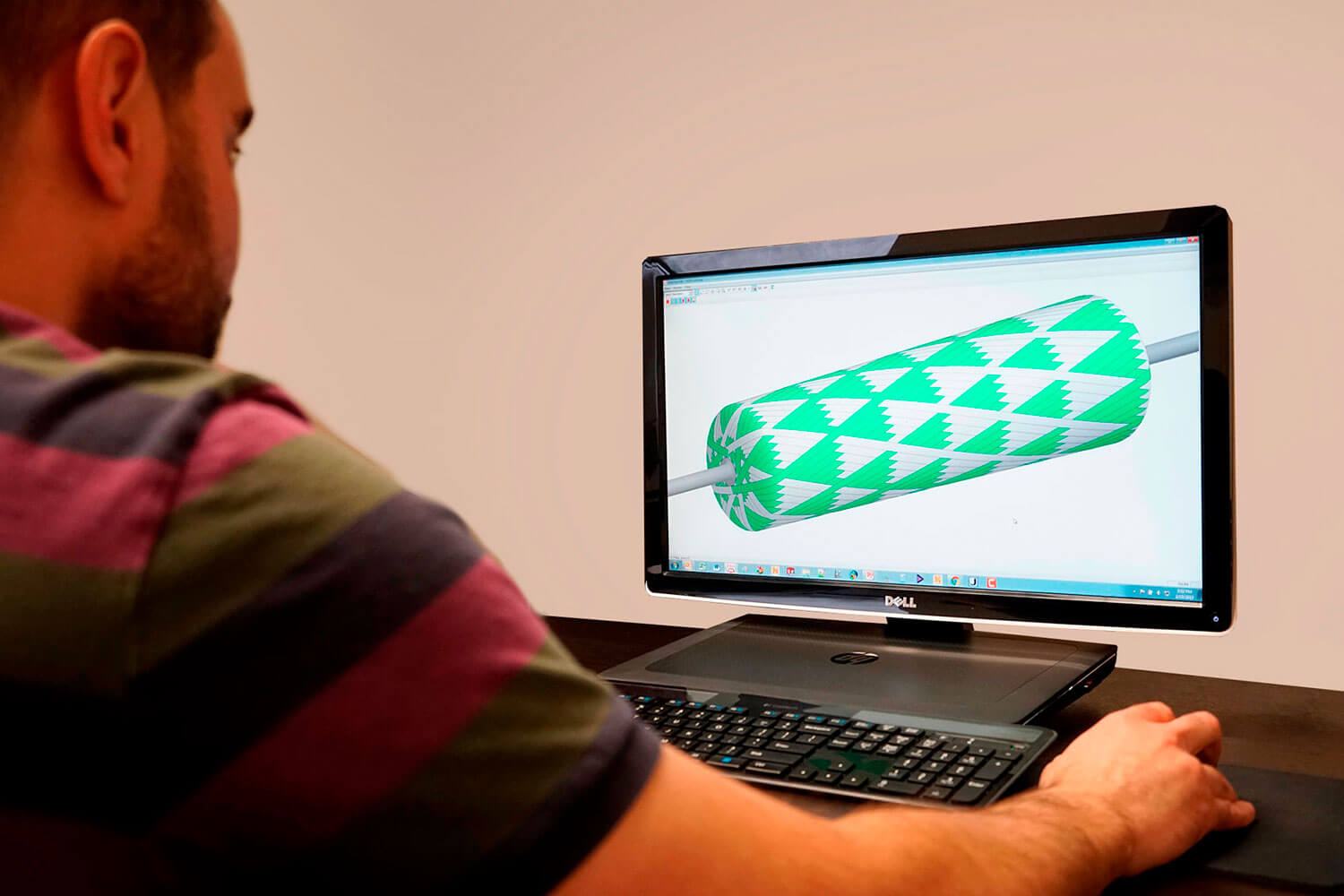

Engineering Technology Corporation is a pioneer in computer-controlled filament winding machinery and developed the world’s first filament winding software, FiberGrafiX®, which provides a wide range of tools to create and optimize fiber paths machine motions.