Engineering Technology Corporation is an expert in the filament winding industry and delivers complete solutions for manufacturing composite parts. In addition to filament winding machinery, the company provides retrofits, automation, design & analysis services, prototyping, and its in-home developed filament winding software FiberGrafiX® which works seamlessly with our winders, as well as the majority of winders available in the market.

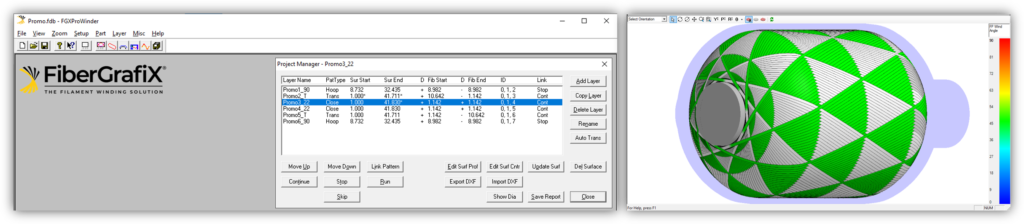

FiberGrafiX® is a reliable tool developed by the pioneers of computer-controlled winding and has been used extensively in numerous companies around the world. FiberGrafiX® has an intuitive user interface and many visualization tools to reduce the iterative process and help you get to the production stage quickly.

FiberGrafiX® provides a complete application suite for creating, organizing, modifying, analyzing, and optimizing filament winding projects. FiberGrafiX® clearly displays data using 3D graphics with data and graphic cursors linking the graphic display with tabular data.

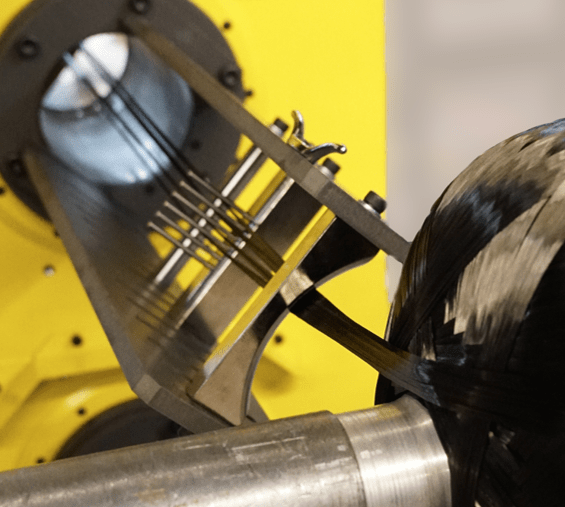

Patterns are created by defining the mandrel geometry upon which the fiber paths are placed in much the same way that layers are wound on the part.

Friction modeling is used to optimize the fiber paths and create stable winding patterns for the wound layers as well as transitional fiber paths from layer to layer. Pattern optimization provides accurate fiber placement at high winding speeds. An FGXImport option allows programming for both axisymmetric and some asymmetric geometry. A finite element interface is available, simplifying the task of creating finite element analysis (FEA) models.

A unique winding motion editor provides an extensive command set to modify machine motion, fiber coverage, time base, and acceleration smoothing. The advanced graphic simulation shows machine motion with the fiber being placed on the mandrel. This allows winding programs for most patterns to be debugged without a winding machine.

Please find more information here: Product Sheet

The company’s priority is customer satisfaction. Engineering Technology Corp. works hard to provide the best products and innovative solutions to serve customers. We’re committed to continuous improvement and feedback-driven changes.

Contact us if you are interested to know more about the software for filament winding machines and the latest trends on the market.