Over sixty years of experience, tried and trusted design practices, years of cost reductions, decades developing custom filament winders and winding systems have led Engineering Technology Corporation to a competitive catalog of cost-effective and reliable standardized machinery that covers the majority of the market needs for filament winding. This standard line enables businesses of all sizes to quickly and affordably build up production capabilities.

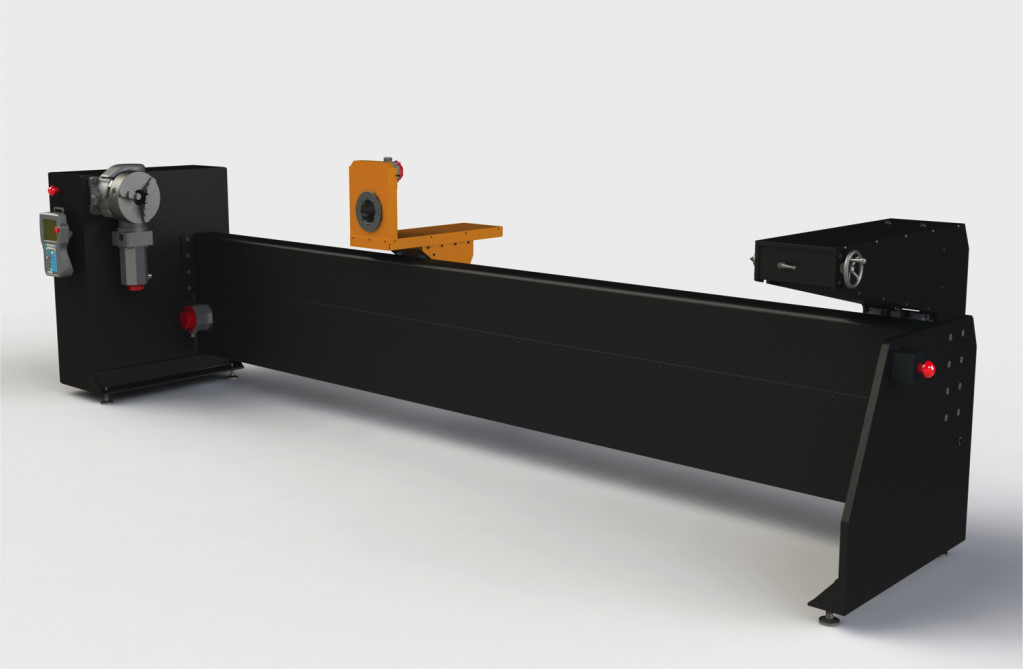

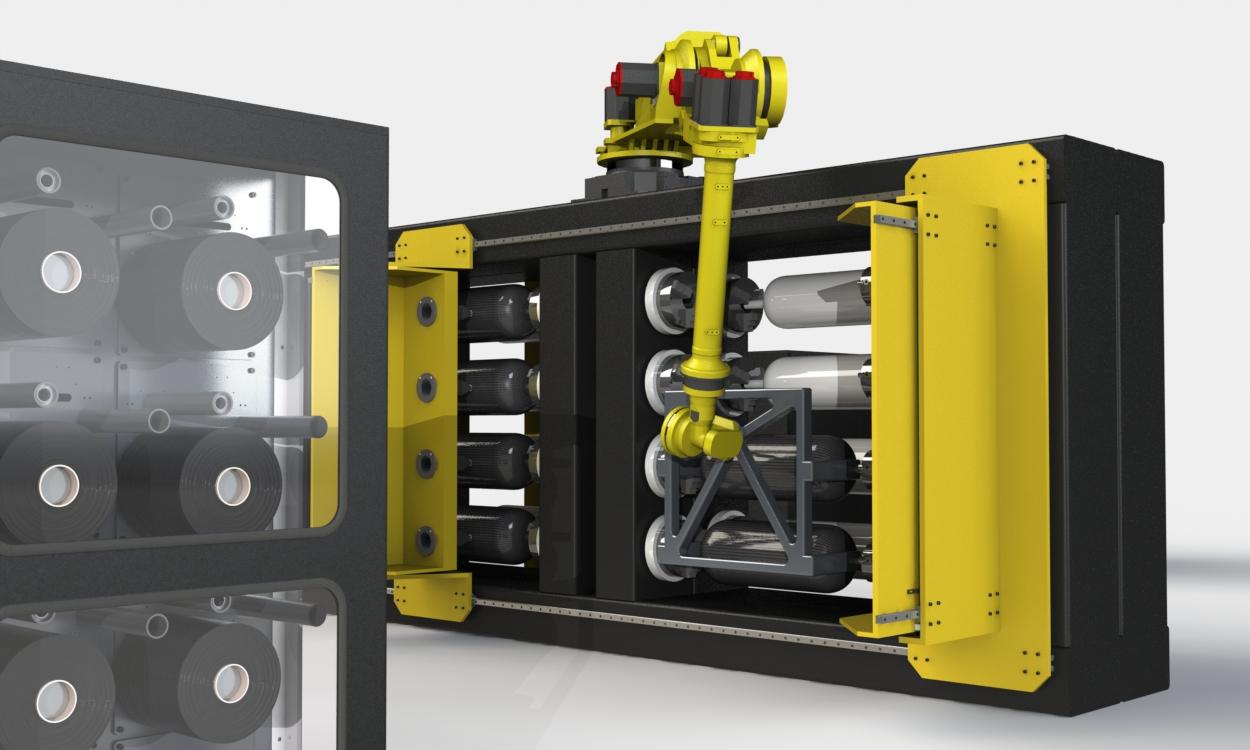

Standard options range from laboratory scale table-top filament winders, made specifically for winding test coupons, up to multi-spindle automated pressure vessel winders with industry-leading fiber payout. Standard filament winders are easy to maintain with readily available spare parts. The customers can count on receiving the same exceptional service that Engineering Technology Corporation has been known for over the past fifty years.

In addition to standardized machinery, Engineering Technology Corporation provides custom production solutions and complete service, including production consulting, onsite machinery installation, process integration, training, and others to meet our customers’ needs for manufacturing composite parts.