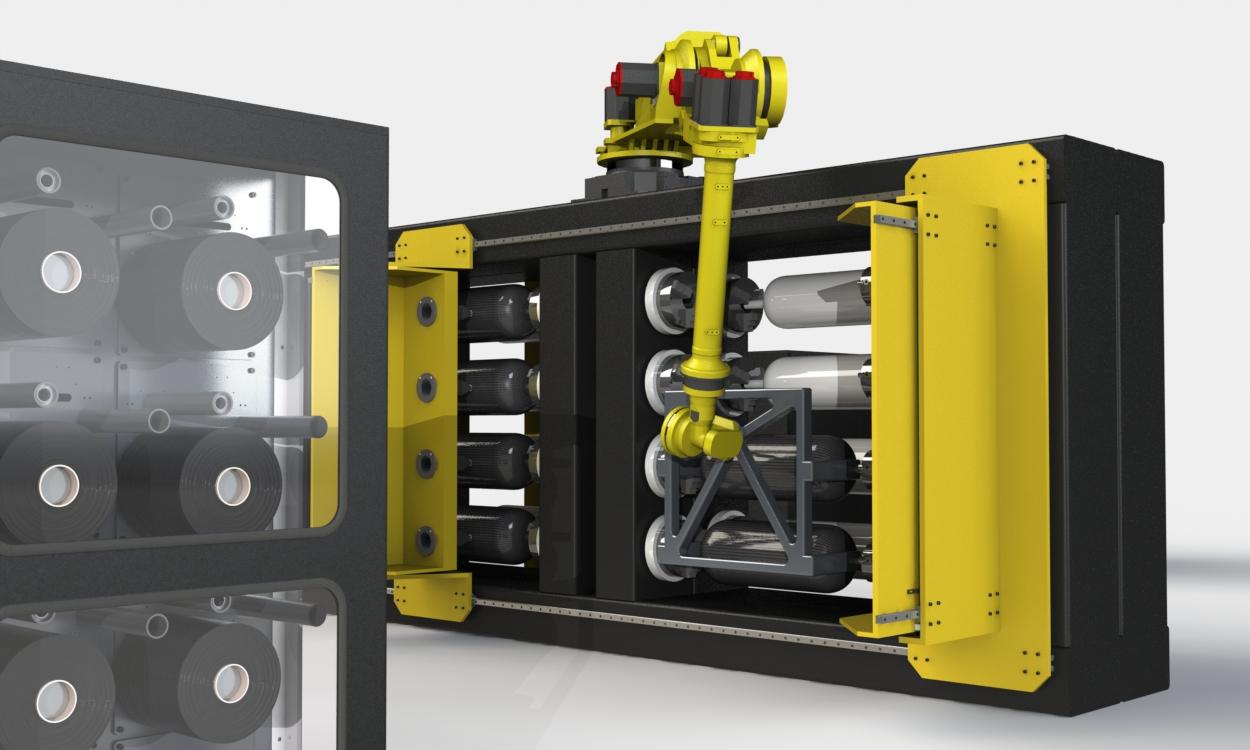

Engineering Technology Corporation has been producing tape-wrapping machines for over 50 years. Tape-wrapping machines are specialized composite manufacturing equipment specially designed to create carbon / phenolic structures. These structures excel in applications where high heat and pressures are encountered. They have been a staple of the aerospace, defense, and space exploration industries since the 1960s.

As interest in carbon / phenolic structures has increased, Engineering Technology Corporation has worked hard to provide the next generation of tape wrapper machines. Engineering Technology Corporation is pleased to offer new standard tape-wrapping machines that offer more precise tape placement, better control over process variables, and less operator interaction than previous machines. Two standard sizes of tape wrapping machines are available for maximum structure diameters of 30 or 60 inches, with custom sizes available for larger structures.

Contact us to discuss your tape-wrapping goals. The experts from Engineering Technology Corp. will provide the best solution for your needs.